Aluzinc Steel

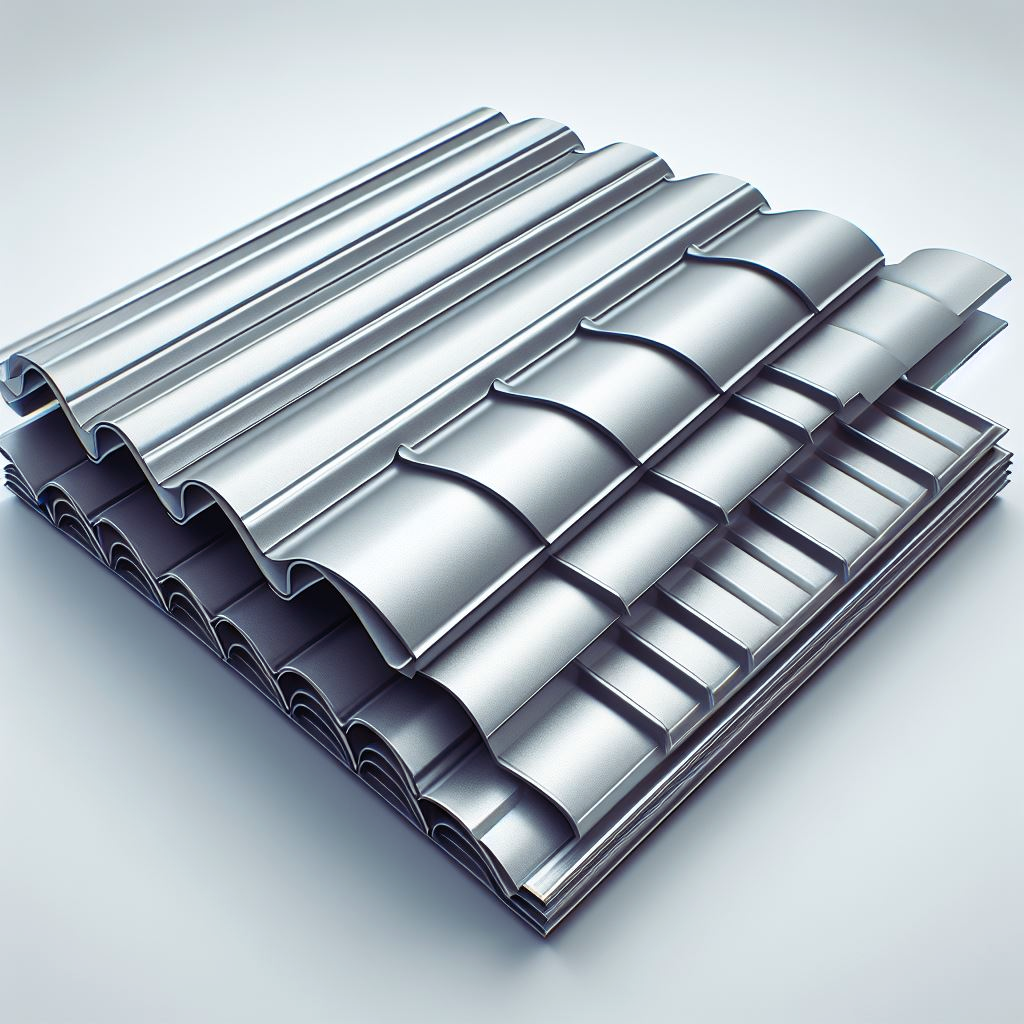

Aluzinc is an aluminium-zinc coated steel sheet that can be used unpainted up to corrosive class C3. The name AZ150 indicates the coat weight of 150 g/m2 per double side. The surface has been treated with SPT (Surface Protection Treatment) to prevent stains during handling and to ease shaping. The Aluzinc Steel which is acms steel is undergoing few tastings to check the product quality. These are PMI test, flattening test, IGC test, hardness test, flaring test, macro test, chemical test, micro test, and mechanical test etc. The item is packed in wooden crates, wooden boxes, and carton boxes to give full safety to the item when internationally shipped.

Metal Vision is a renowned Aluzinc Steel Sheets, Plates, Coil manufacturer, Aluzinc Steel Sheets, Plates, Coil exporter, Aluzinc Steel Sheets, Plates, Coil supplier in Mumbai, Delhi, Chennai, Bangalore, Nigeria, Nepal, Bhutan, SriLankan, UAE, Oman, Saudi Arabia, Ethiopia, Uganda, Malaysia, Thailand, Philippines so on.

It is customary to separate between the aesthetic and technical lifetime. The aesthetic lifetime is a measure of the time it takes for the topcoat to change to such an extent that the appearance no longer meets the requirements. The technical lifetime is the time it takes until the sheet no longer can protect the supporting constructions or foundations of the building.

The layer of Alu-zinc has a thickness of approx. 20 μm (0.020 mm) per side for AZ150. The corrosive speed, i.e., how much of the coating that disappears each year, is a maximum of 0.2 μm in a normal environment (C2) in which Alu-zinc is freely exposed. Due to corrosive and appearance related reasons, the following combinations should be avoided to prevent them from affecting the aesthetic and technical lifetime:

As Well as Aluzinc

• Aluzinc in combination with copper, brass or lead can cause galvanic corrosion. Avoid drainage from constructions and roofs that contain these metals. In particularly aggressive environments, even stainless steel and nickel can increase the corrosive speed of Alu-zinc.

• Aluzinc in contact with high grade woods, damp wood or wood with waterproofing containing copper can cause black rust or corrosion.

• Aluzinc in combination with bitumen products without a UV stabilizer.

• Aluzinc in combination with wet concrete, cement and plastering that are very alkaline can cause discoloration or black rust.

Aluzinc Steel Sheets and Plates

| Aluminium-zinc coated steel sheet AZ150 | According to EN 10142 |

| Thickness | 0.50 ± 0.06 mm 0.60 ± 0.06 mm 0.70 ± 0.08 mm 0.80 ± 0.08 mm 0.90 ± 0.08 mm 0.100 ± 0.09 mm 0.120 ± 0.10 mm 0.150 ± 0.11 mm |

| Minimum bending radius | 1T |

| Protection against corrosion on the edges | Very good |

| Fire Resistance Classification | A1 (EN 13501-1) |

| Reflection of solar heat | 81% (new) 39% (aged) |

| Width | 1600 Max |

| Coating | 70GSM to 300GSM |

| Grades | SGCC, SGCD1, SGCD2,DX51D, DX53D,DX56D, S280GD,S350GD,S550GD, SGC490, GRADE 550 |

| Application | It is a good substrate for organic coating it is generally used in the manufacture of wide sections for wall cladding and insulation cladding. Supplied with a very thin organic finger print free coating for even better performance. |

Corrosive classes in accordance with SS EN ISO 12944-2

| Class | Environmental Corrosivity | Examples of typical outdoor environments in the temperate climate zone |

|---|---|---|

| C1 | Very low | Interior environments. Heated buildings with clean atmospheres, e.g. offices, shops, schools, hotels. |

| C2 | Low | Atmospheres with low level of pollution. Mostly rural areas. |

| C3 | Measurable | Urban and industrial atmospheres, moderate sulfur dioxide pollution. Coastal areas with low salinity. |

| C4 | High | Examples of typical outdoor environments in the temperate climate zone |

| C5-I | Very high (industrial) | Industrial areas with high humidity and aggressive atmosphere. |

| C5-M | C5-M Very high (marine) | Coastal and offshore areas with high salinity. |

Choosing Aluzinc is a declaration of war against mediocrity. It is the choice of visionaries who dare to build the future today. With Aluzinc, architects sculpt the skyline, engineers forge new paths, and designers craft aesthetics that resonate with the soul. Its versatility knows no bounds, making it the ideal candidate for a myriad of applications, from industrial to artistic, functional to decorative.