Hardox Abrasion & Wear Resistant Steel Plates

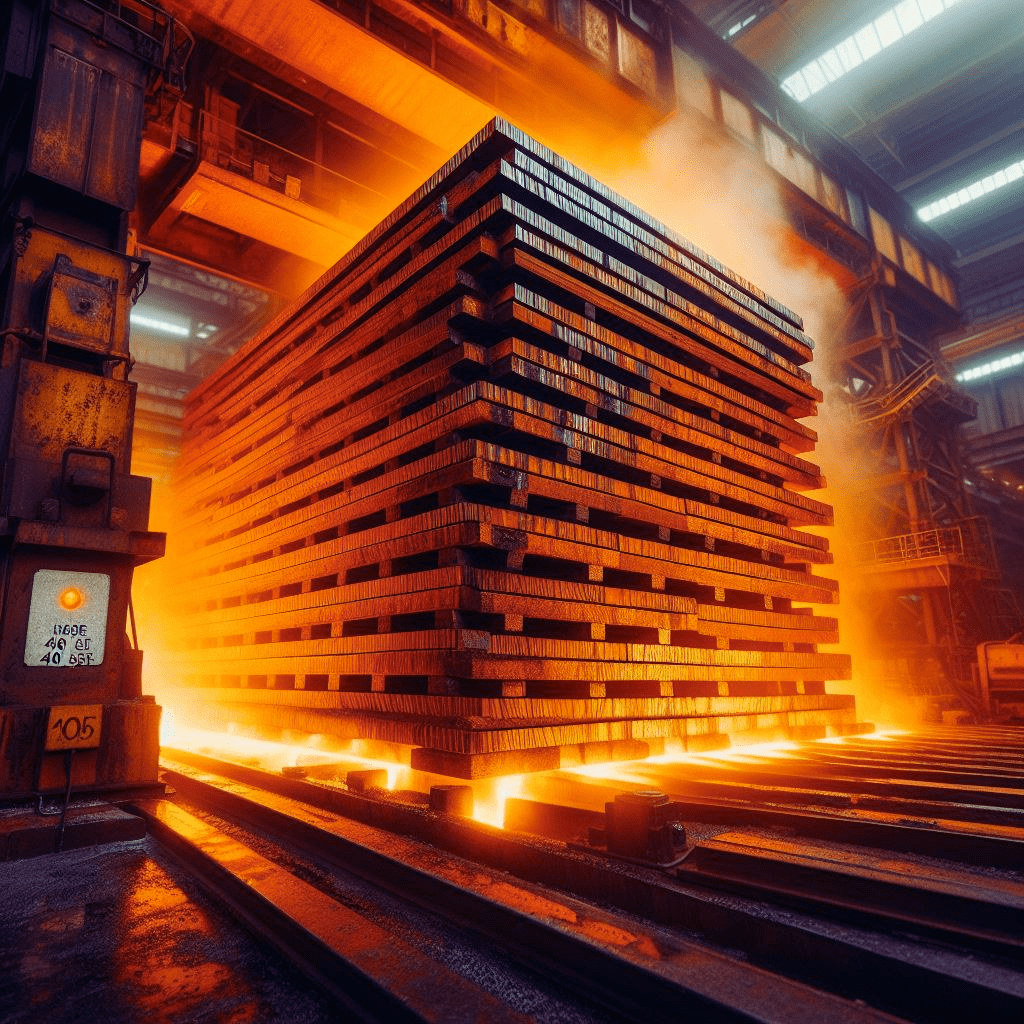

Hardox Abrasion & Wear Resistant Steel Plates is typically made in the as-rolled condition. These types/grades of steel plate products have been developed specifically for long service life in harsh conditions. AR products are suitable for a variety of applications in areas such as mining/quarrying, conveyors, material handling and construction, and earthmoving. Designers and plant operators choose AR plate steel when striving for long service life of critical components, and reduce the weight of each unit put into service. The benefits of using wear-resistant plate steel in applications involving impact and/or sliding contact with abrasive material are immense.

Hardox 450 steel plates are renowned for their exceptional abrasion resistance and durability, making them the go-to choice for industries that demand high-performance materials. With a nominal hardness of 450 HBW, these plates are engineered to tackle the most challenging environments, from the depths of mining operations to the heights of construction sites.

The unique composition of Hardox 450, which includes a mix of carbon and manganese, provides a wear-resistant quality that stands up to extreme conditions. This robust material is not only resistant to wear and tear but also boasts excellent strength and toughness for prolonged service life. Its ability to perform under extreme temperatures and in harsh environmental conditions makes it a versatile and reliable material for heavy-duty equipment.

Hardox 450’s versatility shines in its wide range of applications. It’s extensively used in mining, construction, forestry, and agriculture. Whether it’s excavators, dump trucks, or agricultural machinery, Hardox 450 steel plates ensure reliable and long-lasting performance, even in the harshest working conditions.

While Hardox 450 is synonymous with strength and durability, regular maintenance is key to its longevity. Proper lubrication and storage are essential to prevent corrosion and maintain the structural integrity of the steel plates.

Hardox 450 steel plates are not just another component; they are the backbone of heavy-duty machinery. Their high abrasion resistance and durability underpin their reputation as the material of choice for challenging applications. By adhering to proper maintenance practices, you can ensure that your Hardox 450-equipped machinery delivers optimal performance year after year.

Steel plate for use in abrasive conditions is not typical because it is not governed by any ASTM code or spec. Many steel plate manufacturers produce their own brand of abrasion resistant steel and these are usually distinguished by a brand name followed by the hardness of the steel which is measured in Brinell units.

Metal Vision is the best Manufacturers, Suppliers & Exporters of a wide range of High-quality Hardox-Weldox Pipes & Tubes, Sheets & Plates, Bars & Rod, Buttweld Pipe fittings, Valves, Wires, Angles & Channel in Mumbai, India, Nigeria, Nepal, Bhutan, Srilanka, UAE, Oman, Ethiopia, Uganda, Malaysia so on.

Hardox Abrasion & Wear Resistant Steel Plates

| Material | HARDOX 500 , HARDOX 400 , HARDOX 450 HARDOX 600 SUMIHARD , NICRODUR BRINAR , DUROSTAT , DILLIDUR , JFE EVERHARD |

| Thickness | 3-200mm |

| Width | 500-3000mm |

| Length | 1000-12000mm |

| Heat Treatment | N, Q+T |

| Surface Paint | EP, PE, HDP, SMP, PVDF |

| Export to | Saudi arabia, Kuwait, Qatar, Oman, Yemen, UAE, Iran, Turkey, Kazakhstan, Greece, Singapore, Thailand, Indonesia, Vietnam, South Africa,South America,Brazil, India, Australia, Egypt |